Espresso Machine Disassembly

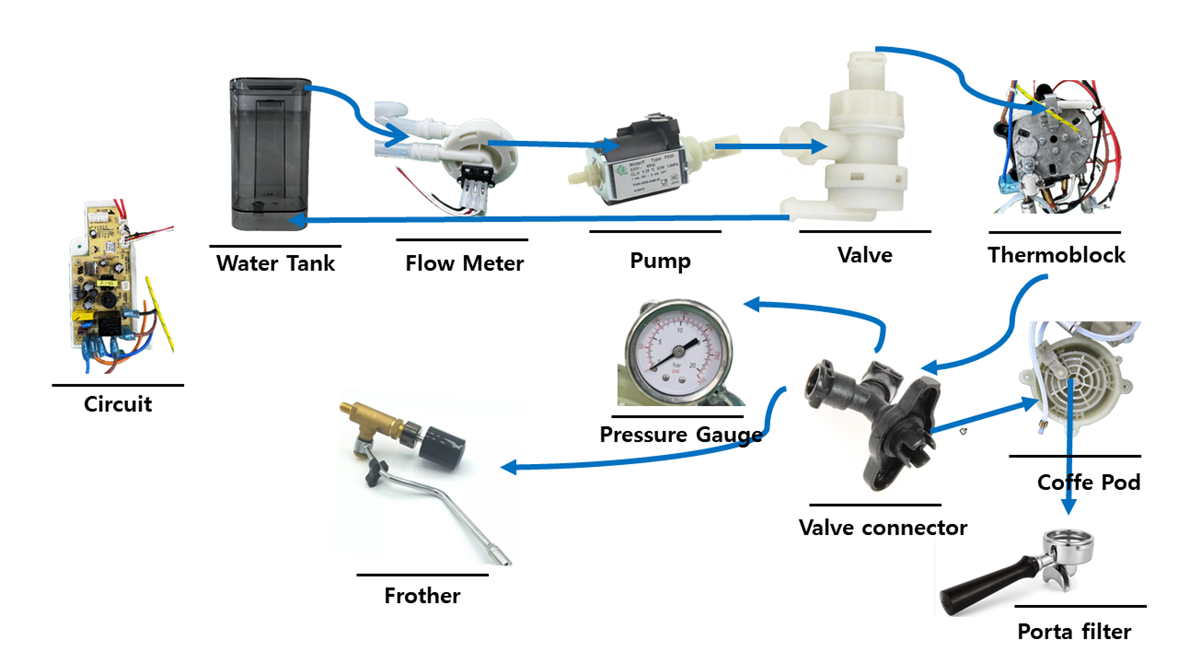

Espresso machine disassembly & analysis about pump

Espresso machine disassembly process to identify structure and constraints.

Introduction

- The espresso machine pump was selected as the main analysis subject due to its role in pressurizing water flow.

- The disassembly process allowed observation of connections, spring-damper structure, and constraints, although internal parts could not be fully measured.

- This limitation required theoretical modeling combined with experimental verification.

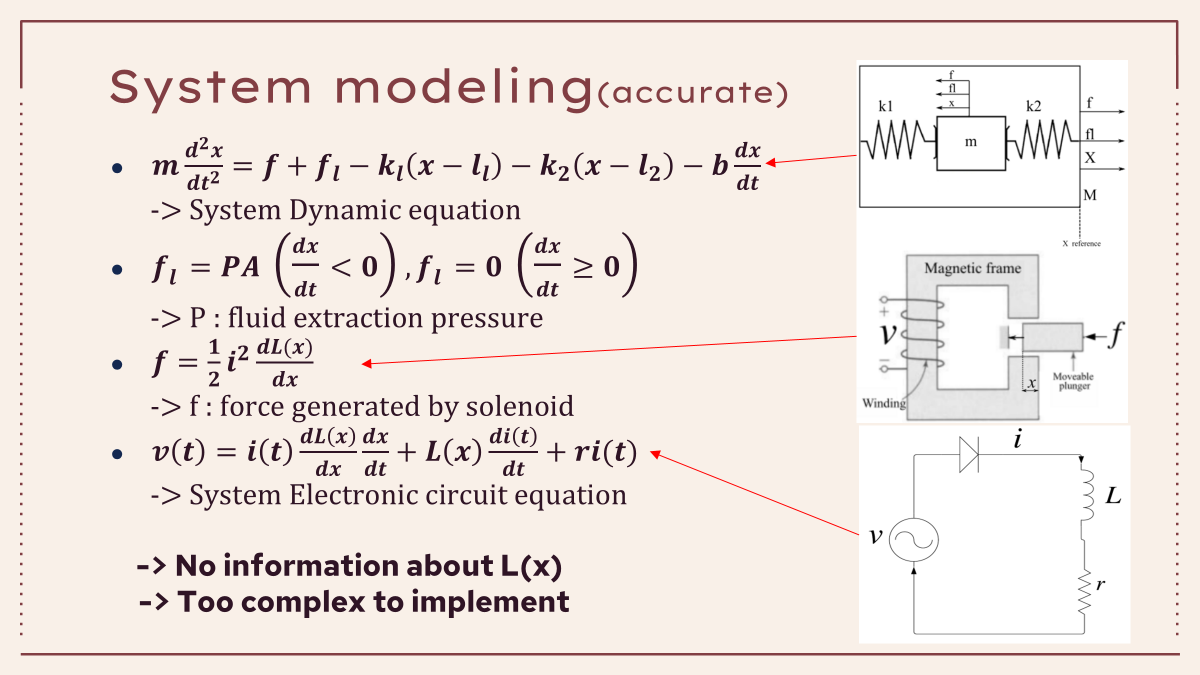

Theoretical Modeling

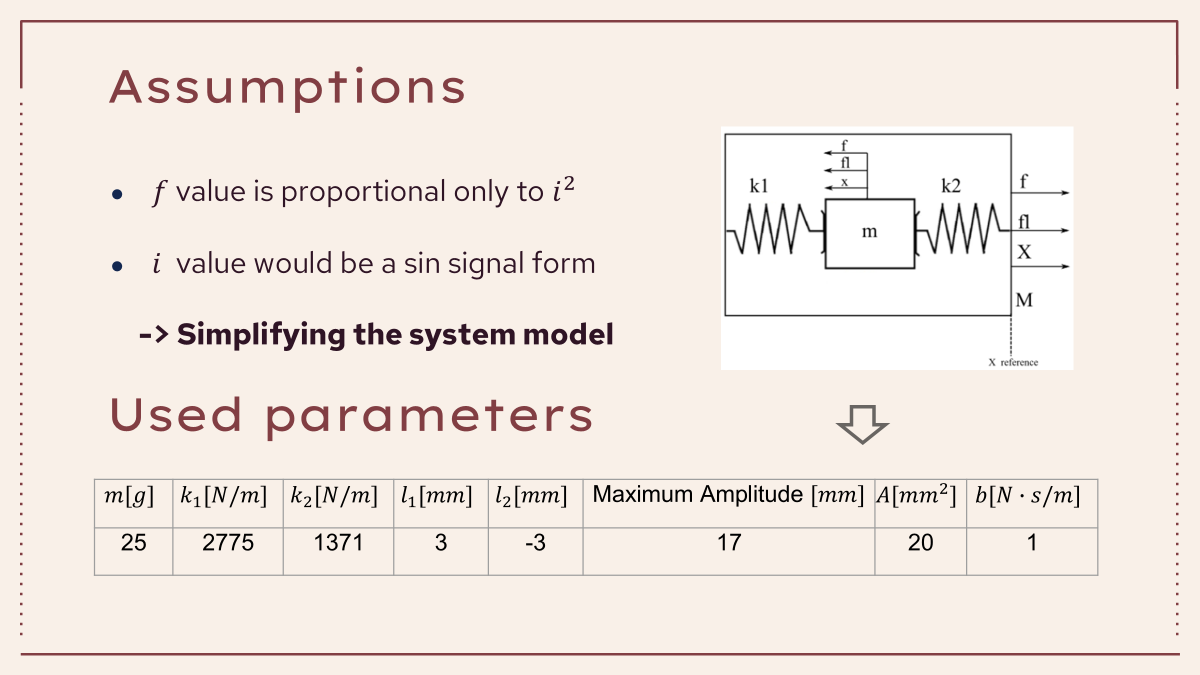

Left: accurate modeling Right: Assumptions

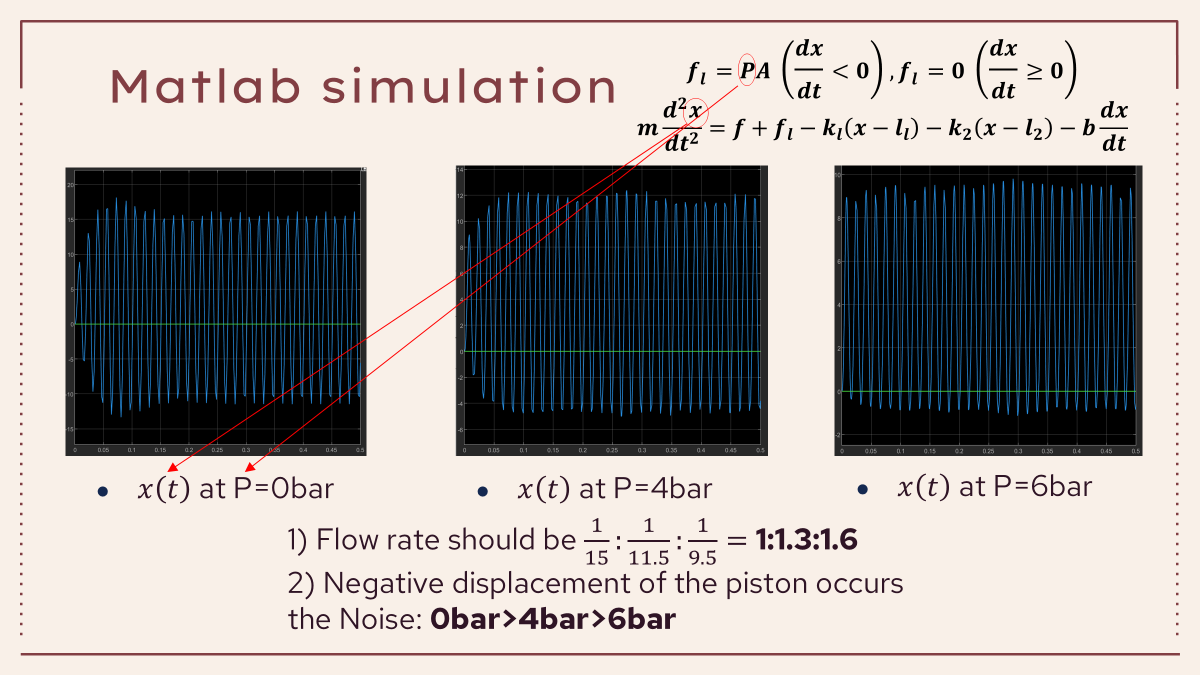

- The pump piston was modeled as a spring-damper dynamic system.

- Assumptions included estimated elastic modulus and damping values due to limited access to internal parts.

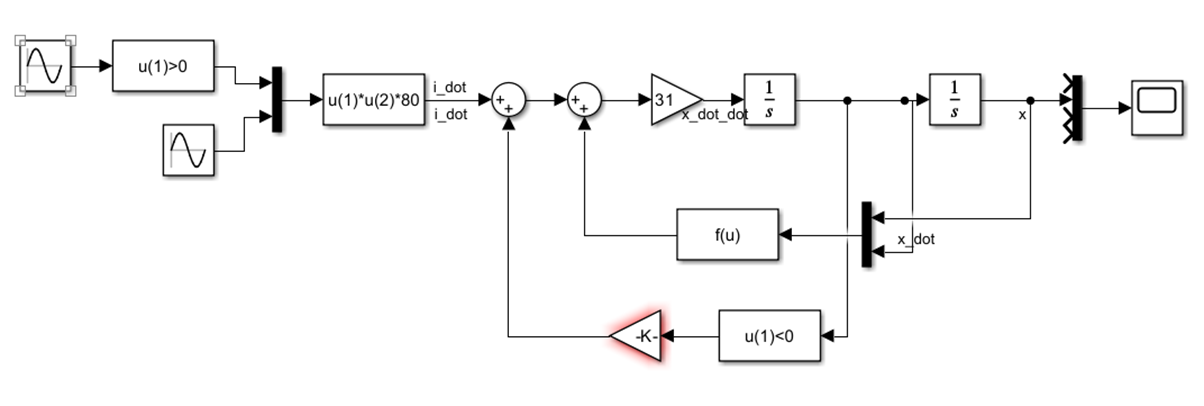

- MATLAB simulation was used to predict piston movement, expected flow rate, and noise characteristics under different pressures.

Experiments

Experimental setup and result for pump flow rate using MATLAB.

-

Flow Rate Measurement

- Measurements at 0 bar, 4 bar, and 6 bar.

- Observed ratio: 1 : 1.36 : 1.65 (close to theoretical 1 : 1.3 : 1.6).

-

Noise Measurement (dB)

- 0 bar: 72.4 dB

- 4 bar: 70.5 dB

- 6 bar: 64.5 dB

- Noise decreased as extraction pressure increased.

Results and Discussion

- Theoretical assumptions and MATLAB predictions were supported by experimental results.

- Minor discrepancies were due to parameter estimation errors, such as unknown spring stiffness.

- Despite limited disassembly, the dynamic system approach was effective.

- The workflow demonstrates system modeling, simulation, and experiment as a transferable methodology.

Conclusion

- The pump analysis combined reverse engineering, dynamic modeling, and experimental validation.

- Key insights:

- Flow rate and noise can be predicted with a spring-damper model.

- Experimental results support the theoretical assumptions.

- Future work: full disassembly and direct measurement of material and spring properties to refine the model.