Optimal Beam Design Project

Term project in Materials and Manufacturing Processes - CFRP-Woodrock composite beam design and testing

Overview

As part of the Materials and Manufacturing Processes course (Team 11), we designed, fabricated, and tested a CFRP-Woodrock composite beam under a 3-point bending test.

The project focused on addressing the challenges of discontinuous layers, voids in lamination, and low stiffness of the foam core.

Idea Formulation

- Initial design made the center thicker to withstand concentrated loads.

- Observed issue: carbon remained intact while the foam (Woodrock) was crushed.

- Proposed a triple-I beam design:

- Allows CFRP to behave as a single continuum.

- Stronger against torsion than a standard I-beam.

- Lamination process simplified, while void formation minimized through careful alignment.

Advantages and Limitations

Advantages

- Strong resistance against lateral bending

- Better load distribution across the structure

- Enhanced global rigidity

Limitation

- Buckling risk identified, mitigated by using Woodrock reinforcement between webs

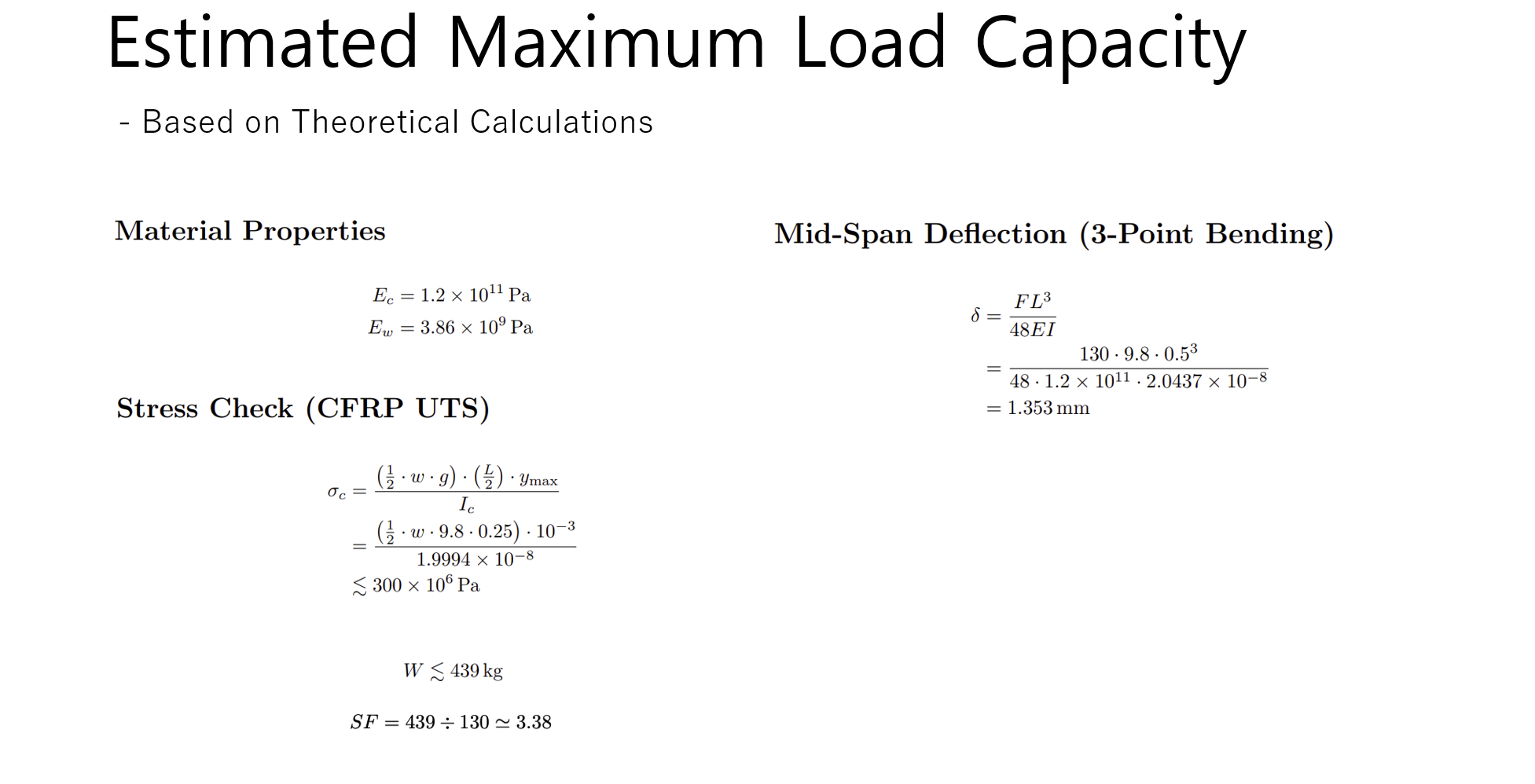

Theoretical Analysis

Process and Analysis

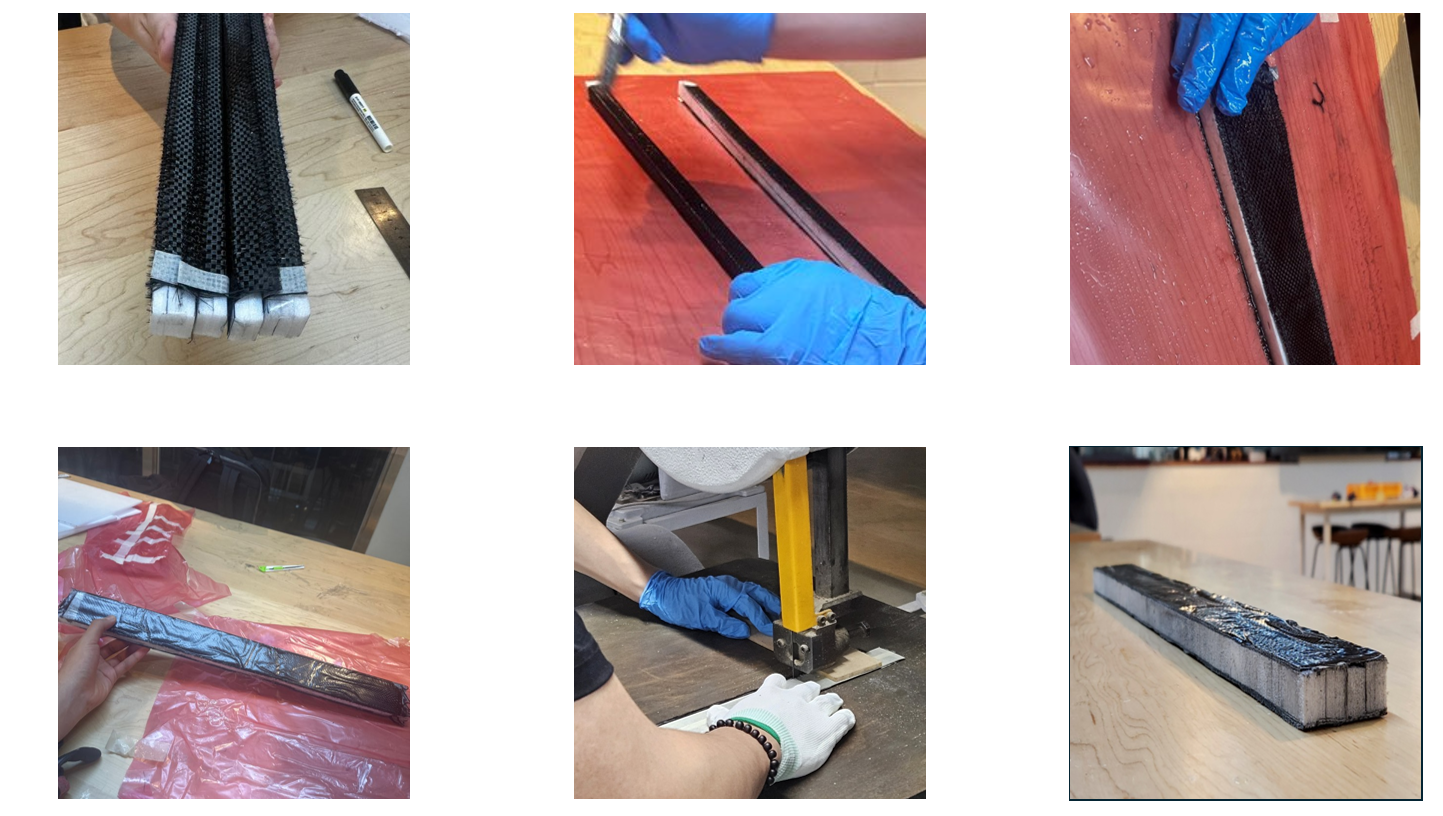

- Manufacturing: Laminated and bonded CFRP with Woodrock, emphasizing vertical alignment to reduce voids.

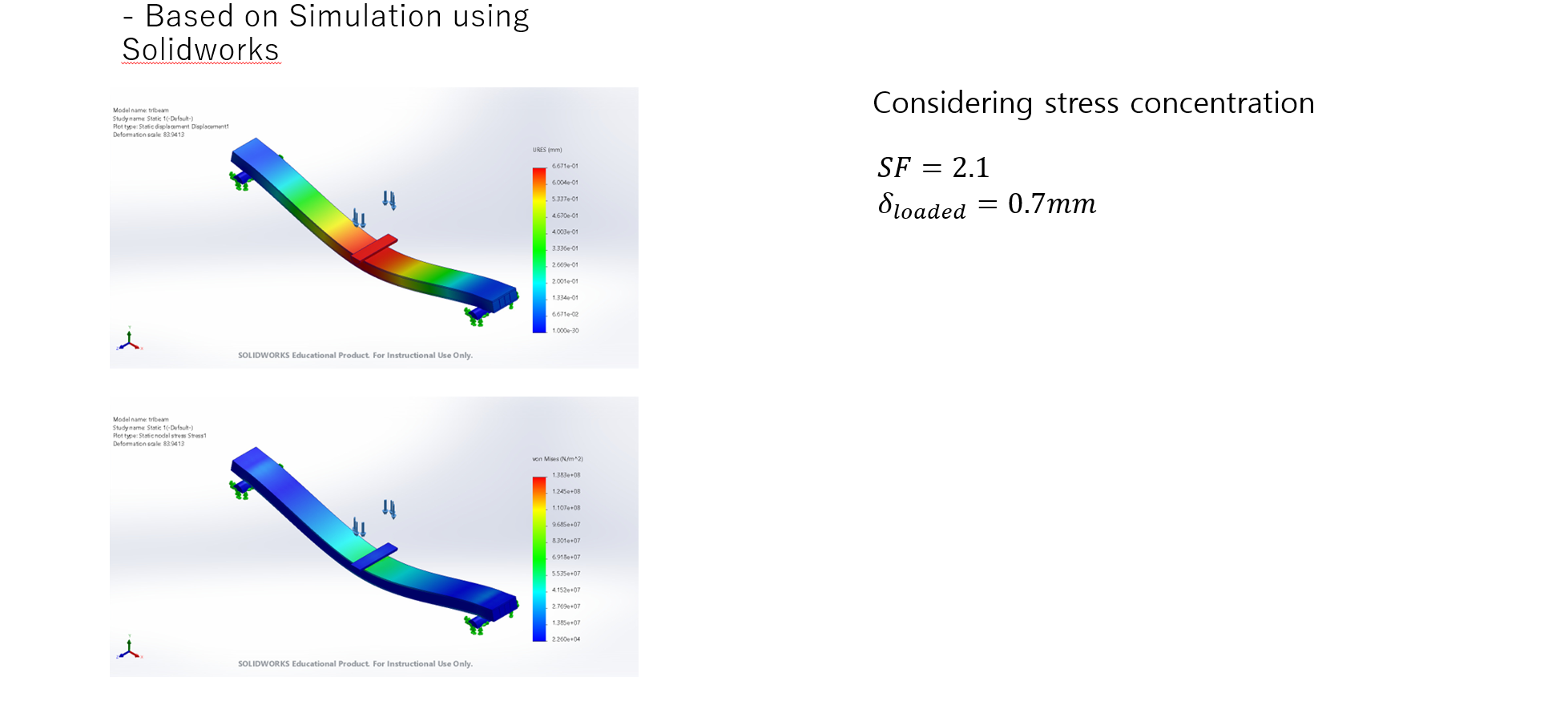

- Simulation: Performed SolidWorks stress analysis to estimate maximum load capacity, accounting for stress concentration.

- Testing: Conducted 3-point bending experiments and compared results with theoretical and simulation predictions.

Outcomes

- The fabricated beam (178 g) successfully withstood the maximum allowed load of about 140 kg without failure.

- This was the highest load-bearing result among all 16 teams, even though the final ranking was 4th place due to scoring criteria.

- Results validated both the theoretical and simulation predictions, highlighting the effectiveness of the triple-I beam design.

Key Takeaways

- Learned the importance of void minimization and structural continuity in composite design.

- Experienced the full cycle of design, simulation, fabrication, and testing.

- Gained practical skills in teamwork, composite material handling, and stress analysis.